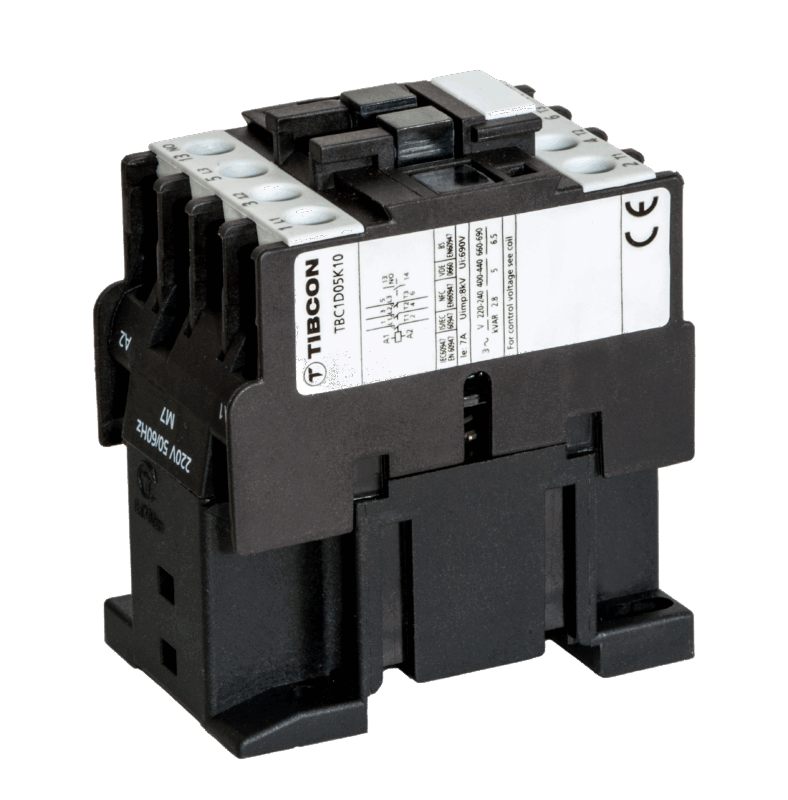

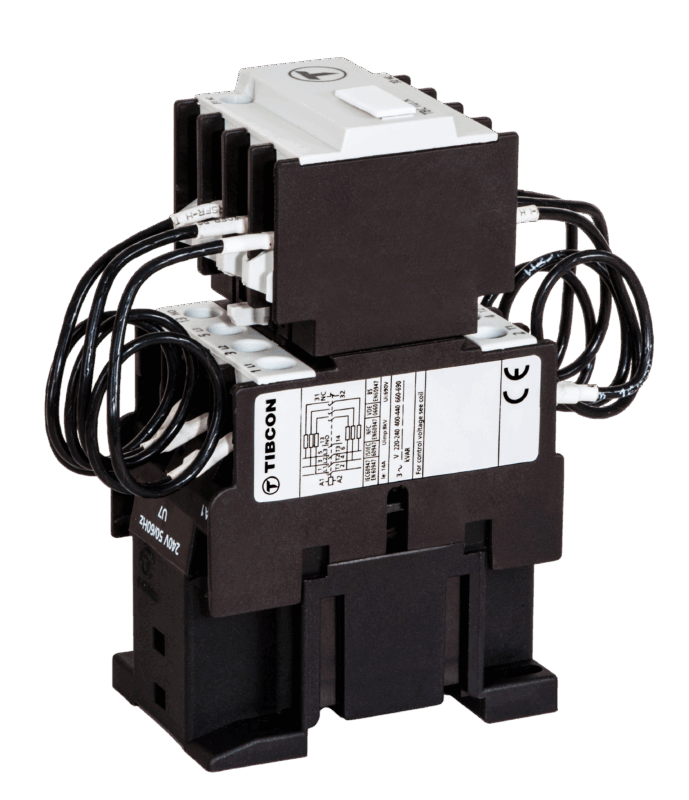

Static Contactor Systems: Definition and Operating Principle

Static contactors are electronic devices without moving mechanical parts used to control loads in electrical circuits. While traditional mechanical contactors use moving contacts to enable or disable an electrical current, static contactors use semiconductor elements (usually triacs or thyristors).

Static contactors enable the transmission or disconnection of electrical parameters such as voltage and current through electronic circuits. These systems are typically used in applications where fixed loads are controlled and are particularly notable for their energy efficiency, long lifespan, and low maintenance requirements.

Advantages of Static Contactor Systems

Low Maintenance Requirement

Static contactors have no moving parts. This prevents mechanical wear and tear, resulting in a much lower maintenance requirement and failure rate.

High Durability and Long Life

Static systems have a much longer lifespan than mechanical systems. Electronic components are not affected by mechanical wear, which increases the device’s durability.

Fast and Precise Control

Electronic components can respond much faster than mechanical contactors. This provides a significant advantage in applications requiring rapid on-off operations.

Low Noise

Because static contactors have no moving parts, they do not produce noise during operation. This is a significant advantage, especially in noise-sensitive environments.

Energy Efficiency

Electronic circuits can operate more efficiently by minimizing energy losses. This leads to long-term energy savings.

More Compact Design

Static contactors can be smaller in size, allowing for more compact systems.

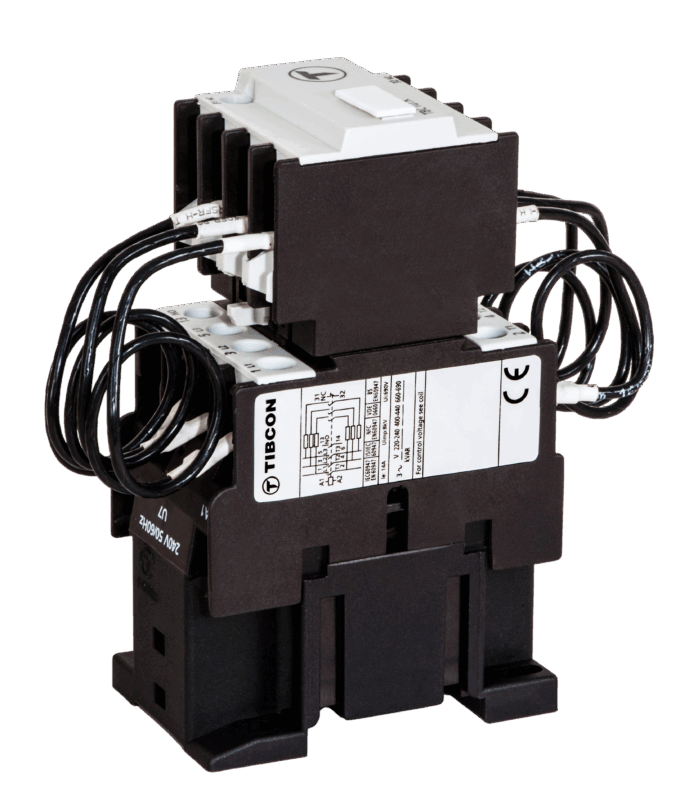

Uses of Static Contactor Systems

Static contactors are typically used in the following areas:

Heating Systems: In electric heating systems, static contactors are used to regulate energy flow.

Ventilation and Air Conditioning Systems (HVAC): In HVAC systems, static contactors are preferred for starting and stopping motors.

Lighting Systems: They can be used in industrial or commercial lighting systems to achieve energy efficiency.

Motor Control Systems: Static contactors are used to turn motors on and off, especially when operating at constant speed.

High Power Applications: They can also be used to control large electrical loads.

Disadvantages of Static Contactor Systems

High Initial Cost: Electronic components and circuit designs are generally more expensive. This can lead to high initial costs.

Limited Load Capacity: Static contactors may have limited capacity, especially in high-current applications. Therefore, mechanical contactors may be preferred in some larger applications.

More Complex Design: Static systems may require more complex circuit designs than mechanical systems, creating additional factors to consider during the design phase.

Conclusion

Static contactor systems are a preferred technology for industrial and commercial applications, providing high efficiency, low maintenance, and long life. Thanks to their electronic-based structure, they offer fast and precise control, energy efficiency, and environmentally friendly solutions. However, some disadvantages, such as initial cost and limited capacity, should also be considered.

As with any system, the use of static contactor systems should be determined according to the application requirements. They can be an ideal choice for applications requiring high reliability and long life.