The main causes of capacitor explosions can be listed as follows:

• Exposure to excessive heat,

• Problems caused by harmonic distortion,

• Voltage imbalances,

• Capacitor banks replaced without applying the equal aging method,

• Reactive power control relay not complying with standard discharge times (minimum acceptable time: 30 seconds).

The main causes of capacitor heating:

• Harmonics in the system,

• Improperly designed panel designs,

• Improper product placement within the panel (e.g., the filter should be on top and the capacitor on the bottom).

According to the international IEC 60831 standard, the internal discharge resistance is designed to reduce the voltage to below 50 volts within 60 seconds. However, in practice, a period of 30 seconds is considered appropriate. For shorter periods, it is recommended to add a discharge coil or resistor to the capacitor input.

According to the international IEC 60831 standard, the internal discharge resistance is designed to reduce the voltage to below 50 volts within 60 seconds.

It is not suitable to use harmonic filters with single-body capacitors designed for 400V and 400-440V ranges. In filtered compensation systems, the voltage increases due to the filter connected in series with the capacitor. This increase is approximately 7% at the commonly used 7% tuning frequency.

In this case, the voltage across a capacitor with a nominal voltage of 400V can rise to 428V. A capacitor operating continuously at this level may be damaged in a short time. The maximum voltage overvoltage values specified in the IEC 60831-1 standard regarding voltage withstand are as follows:

• Un + 10%: 8 hours/24 hours,

• Un + 15%: 30 minutes/24 hours,

• Un + 20%: 5 minutes/24 hours,

• Un + 30%: 1 minute/24 hours.

This situation usually arises for the following reasons:

• Harmonic distortions,

• Voltage increase,

• High peak currents.

To prevent these situations:

• A compensation contactor should be used at the upper limit of the capacitor value,

• A harmonic filter should be added,

• Discharge times should be adhered to. In this case, the voltage across a capacitor with a nominal voltage of 400V can rise to 428V. A capacitor operating continuously at this level can be damaged in a short time. The maximum voltage overvoltage values specified in the IEC 60831-1 standard regarding voltage withstand are as follows:

• Un + 10%: 8 hours/24 hours,

• Un + 15%: 30 minutes/24 hours,

• Un + 20%: 5 minutes/24 hours,

• Un + 30%: 1 minute/24 hours.

Failure to select a capacitor with the appropriate value

• Matching of harmonic resonance values.

Measurements must be requested to determine the correct resonance value. Deviations from the capacitor values to which the harmonic filters are connected can affect the resonance frequency and reduce system performance.

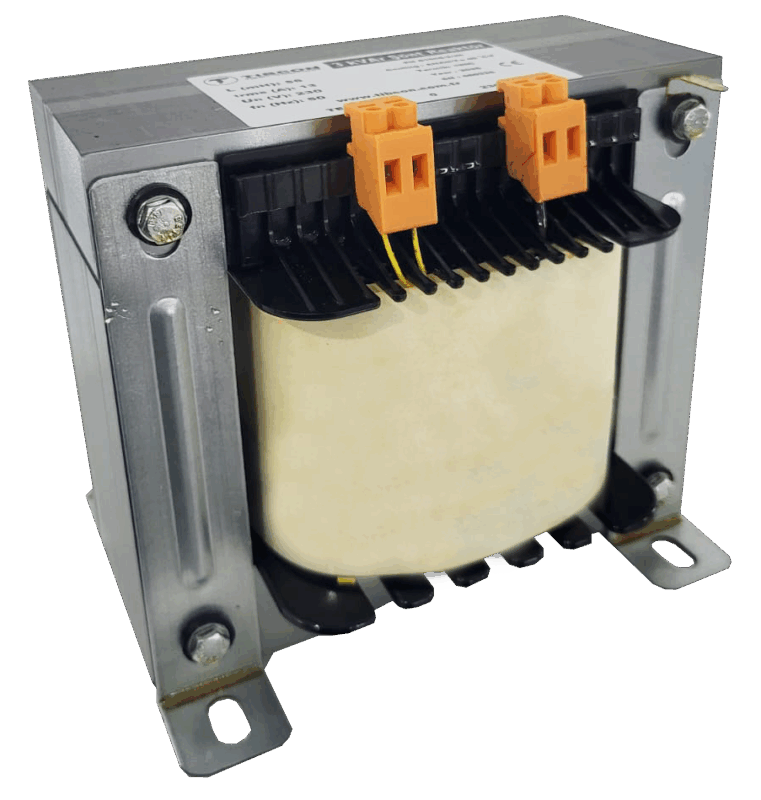

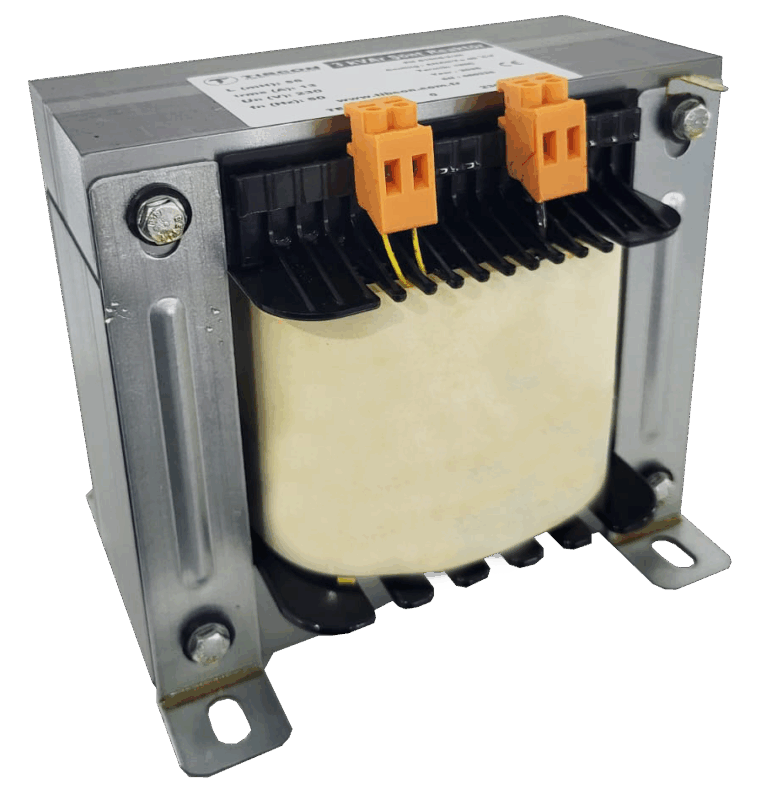

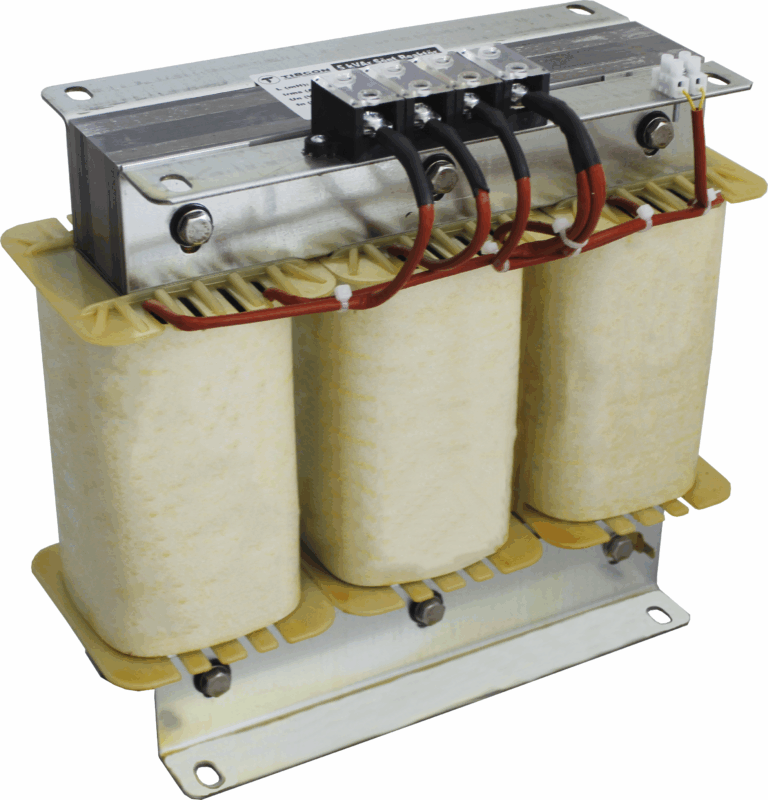

Panels must be designed to provide adequate airflow to prevent harmonic filters from causing heat buildup.

Selecting based on the filter is the most appropriate approach. Otherwise, selections based on the capacitor may reduce the effective values. For example, in a 1000 kVAR 525V system, the effective value obtained with the p7 filter drops to 621 kVAR. For this reason, accurate calculations are important in filtered compensation.

The system causes capacitive penalty on the meter side, but this situation is not observed in the relay. The relay will only compensate for the data it detects. To eliminate this incompatibility, the system must be connected after the current transformer and monitored with reactive power relays compatible with the GES system.

In this case, a detailed check of the system is required. It is necessary to identify the loads connected before the current transformer, determine whether there is a meter error, and check the accuracy of the reactive relay.

SVC (Static Var Compensator) or inductive shunt reactors should be included in the system, taking into account the cable type and length. In such cases, you can contact us for professional support.

The SVC should be determined based on the level of capacitive loads generated in the system. These values can be determined using monthly, weekly, or 24-hour meter readings. In addition, XLPE cable length, UPS power, and non-linear loads (such as LED lighting) should also be taken into account.

Noise from capacitors is usually a problem seen in fixed groups and is caused by high voltage. In addition, faulty manufacturing can also cause this problem.

Harmonic distortions can cause:

• Overheating in electromechanical devices and cables,

• Mechanical vibrations in machines,

• Abnormal operation in ignition circuits,

• Voltage surges and cable punctures,

• Malfunctions in electronic devices and computer cards,

• Losses and explosions in power capacitors,

• Unexplained tripping of circuit breakers and switches. To prevent these failures, harmonic filters should be added to the compensation system.

Harmonic distortions are usually caused by non-linear loads. These include:

• Uninterruptible power supplies,

• Motor starters and drives,

• Computers and electronic lighting,

• Welding machines,

• Power electronics converters. These devices increase harmonic distortion in the grid.

Long energy transmission lines,

• DC drives,

• Facilities with a high proportion of semiconductor devices,

• Hospitals, schools, and laboratories where LED and fluorescent lighting is common.

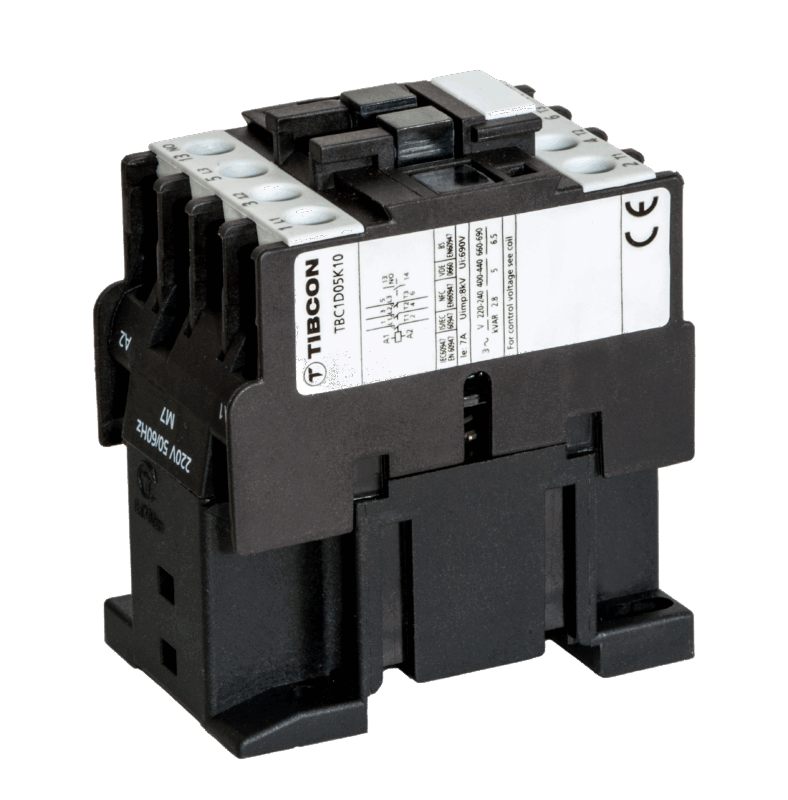

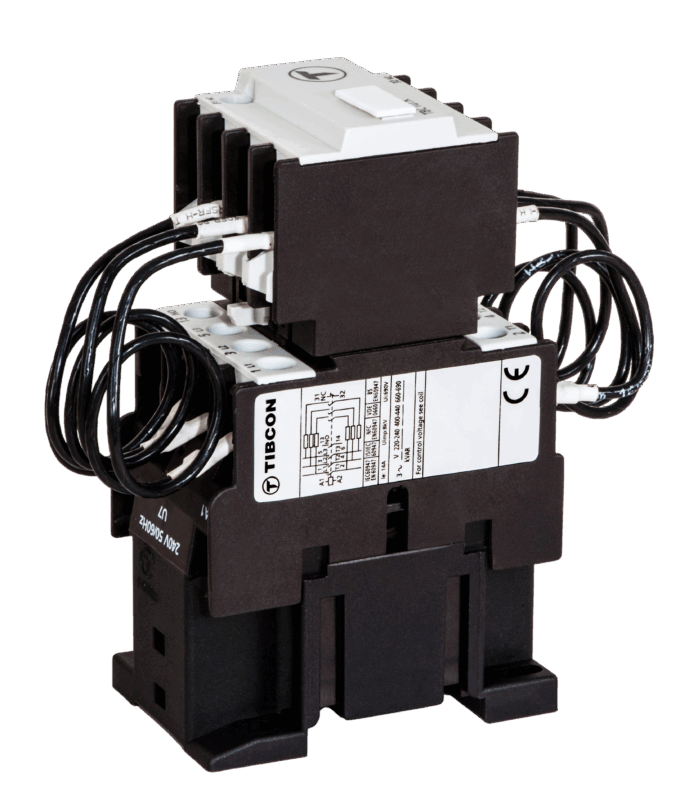

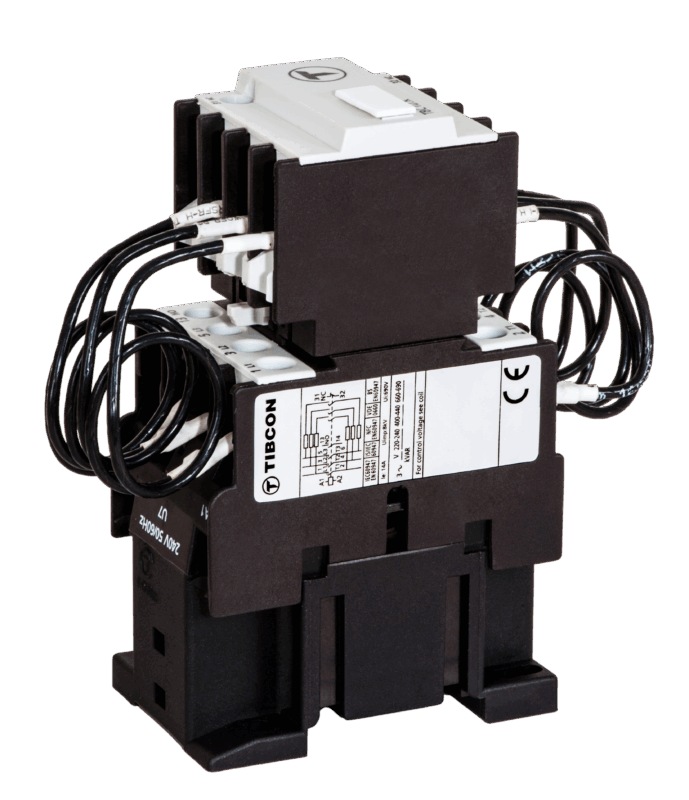

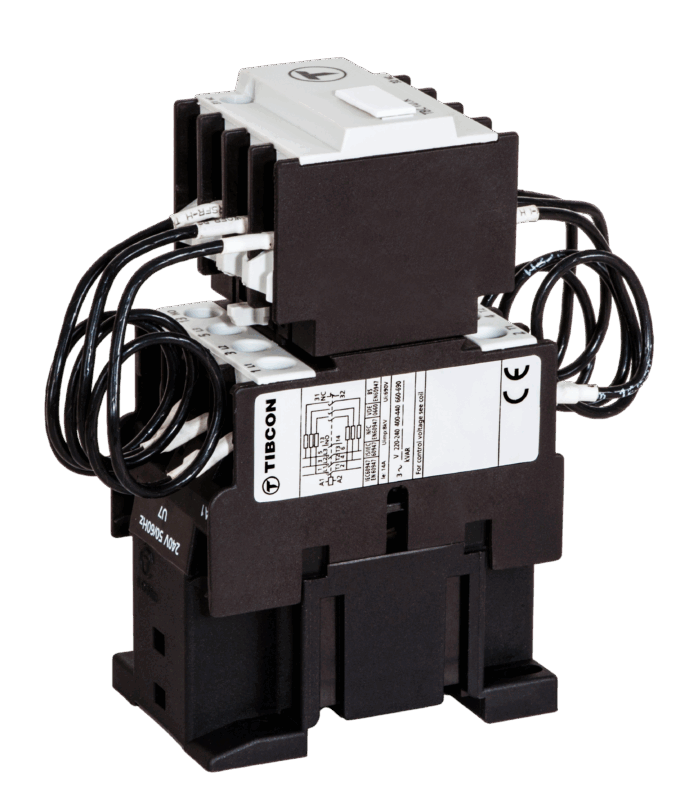

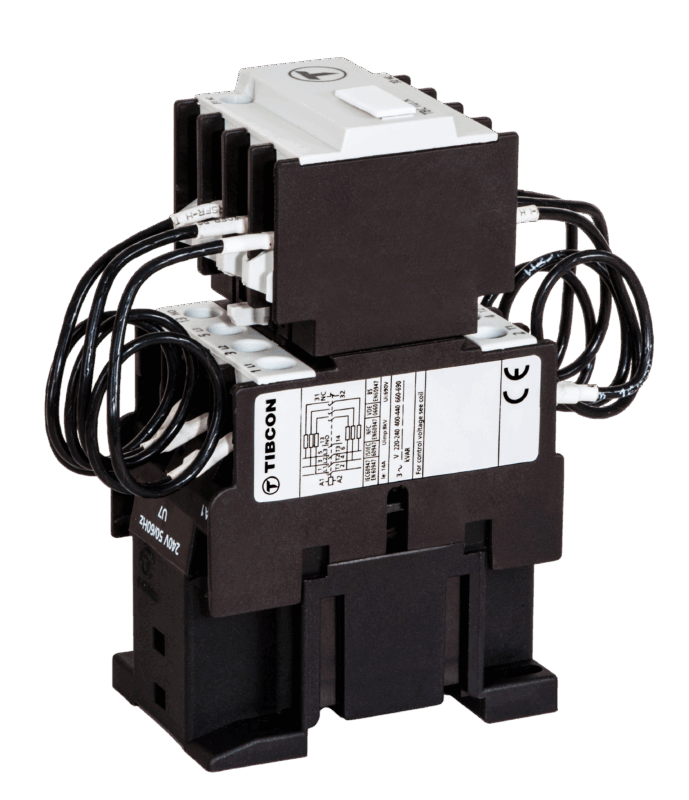

Static contactor-based compensation systems are used for reactive power compensation of loads that suddenly come online and remain in the circuit for a short time. These systems provide solutions, particularly in facilities with high levels of sudden load changes, such as cranes, arc welding, and press machines.

In thyristor-based fast compensation systems, thyristor modules designed specifically for compensation are used instead of conventional contactors. Thyristors enable capacitors to be connected within 10 ms and prevent inrush currents.

Provides accurate and fast compensation,

• No reactive power penalty,

• Extends the life of capacitors,

• Reduces maintenance costs,

• Saves on losses,

• Compensation power can be increased according to need thanks to the modular system.